The possible causes and remedies of the engine oil lubricating system

We use affiliate links and may receive a small commission on purchases. Read more about us.

Low oil pressure, internal and external oil leak, sounding valve, or connecting rod are some of the possible symptoms of an engine’s oil lubrication system error.

One does not need to be an automobile engineer to diagnose an engine’s lube system error.

I am here to point out some of the probable causes of oil lubricating system errors and how you can solve such issues on your own.

Point to be noted, if you have never worked with an engine or do not know the basics of engine troubleshooting, it is always a better option to do the job with the help of a professional.

Before we jump into the problem pointing and diagnosis section, here are some of the basics you might want to know about the engine lubrication system-

What is an engine lubricating system?

An internal combustion engine consists of multiple moving parts that create high friction and temperature when the engine is running.

An engine lubrication system lubes the moving parts of an engine to prevent scoring, burning, or any internal damage.

The engine lubrication system includes a greasy and high viscosity fluid that runs through the moving parts of the engine to reduce the friction and temperature that those moving parts generate when the engine is running.

HOW DOES THE ENGINE LUBRICATING SYSTEM WORK?

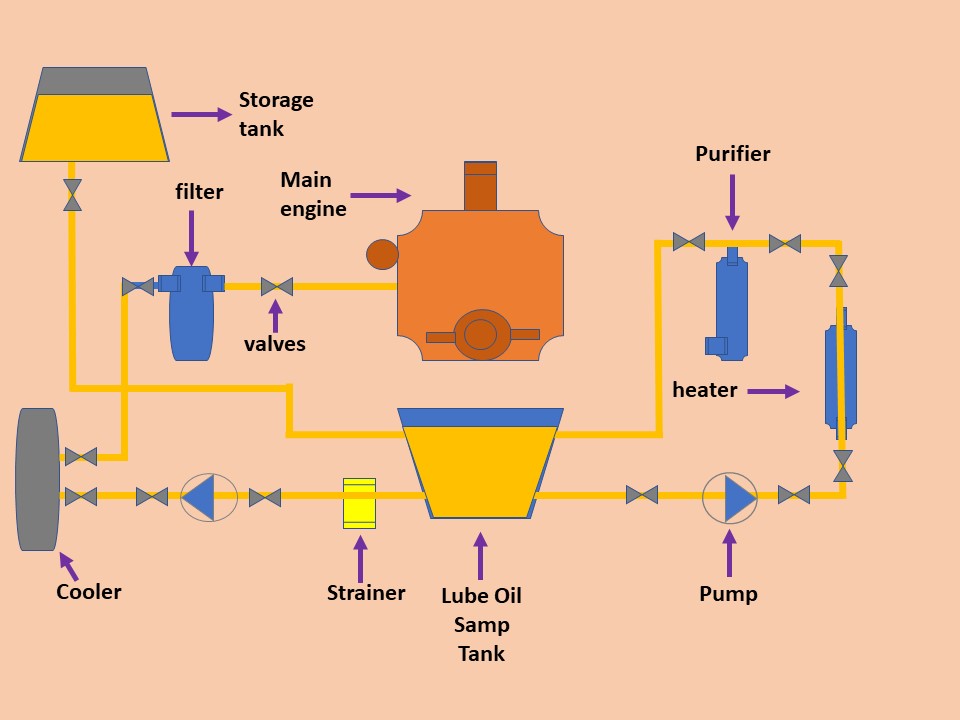

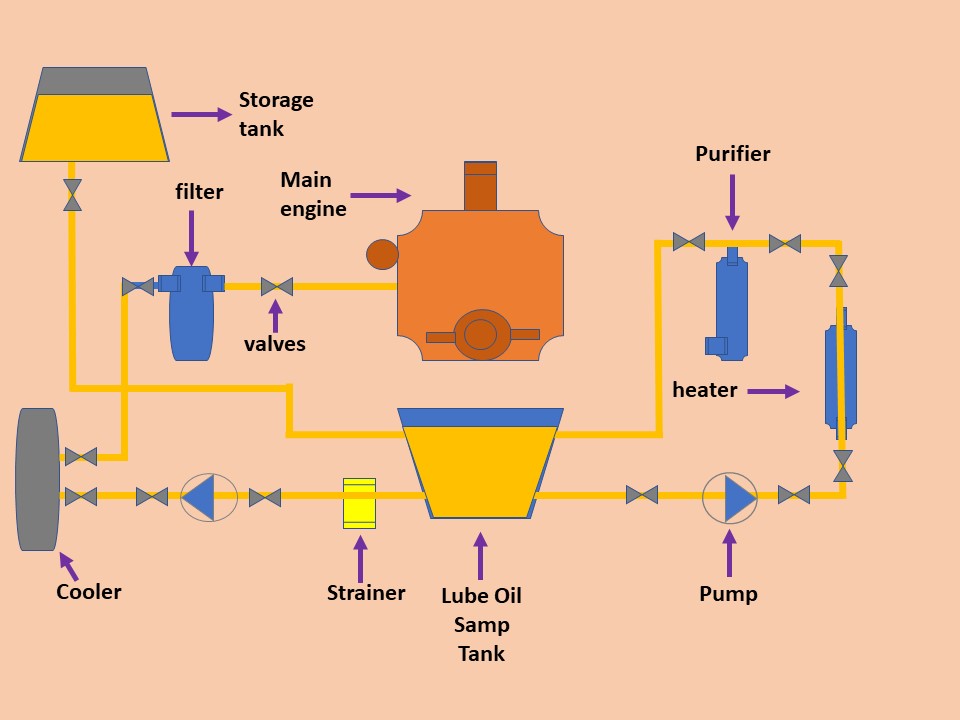

The main engine’s oil lubrication system consists of several different organisms that work combinedly to keep the system running.

Here are the main parts of an engine’s lubrication system-

- Lube oil samp tank (contains the oil for lubrication)

- Strainer (removes larger particles)

- Pump (transfers fluid from one location to another)

- Cooler (cools the heated oil that comes out of the engine)

- Filter (filtrates to prevent contaminants)

- Heater (ensures better purification by lowering the viscosity)

- Purifier (removes dirt and water)

- Storage tank (stores lube oil)

- Valves (controls the flow of fluid)

If the level of lube oil goes down in the Lube oil Samp tank, the open storage tank supplies oil to the samp tank by Gravity.

When the level of lube oil in the samp tank comes to the right proportion, a sounding happens that closes the valve.

Therefore, lube oil stops transmitting from the open storage tank to the samp tank.

Possible engine oil lubricating system problems

Now that we have the basics of how an engine’s oil lubricating system works, let’s talk about the problems one may face with the lubricating system and how to diagnose those problems-

The top five symptoms of a main engine’s oil lubricating system error are-

- Low oil pressure

- Higher oil consumption

- Sound from the main bearing

- Sound from the connecting rod

- Sound from the valve

Now, let’s find out the probable reasons behind those problems and the ways to solve the issues-

1. Low oil pressure

Probable reasons | Diagnosis |

Low oil level | Pour oil to the right level. |

Faulty oil pressure sending unit or warning light | Requires new oil pressure sending unit or warning light installation |

Diluted oil | Drain the loaded oil and refill the tank with the right graded oil. |

Weak relief valve | Install a right-sized relief valve |

Decayed oil pump | Replace the stock oil pump |

Damaged or broken oil line | Replace the damaged oil line |

Stucked oil filter | Change the oil filter |

High bearing clearance | Repairing or measuring the appropriate bearing clearance |

2. High oil consumption

If the engine’s oil lubricating system is consuming more oil than expected, this can be because of three probable reasons-

- External oil leak

- Internal oil leak

- Oil leaks around the piston and piston ring

External oil leak

Probable reasons | Diagnosis |

Damaged valve cover or fuel pump gasket | Replace the gasket |

Lose timing gar cover | Change the gasket and tighten it according to the right torque level |

Oil pump gasket or drain plug | Replacing the oil pump gasket or drain plug |

Damaged oil seal of front and rear main bearing | Change the oil seal |

Oil line in the oil filter gasket or filter | Replacing the gasket and repairing the oil line. |

Closed crankcase outlet vent | Cleaning the vent |

Internal oil leak

A faulty crankcase ventilation valve is one of the primary reasons why an internal oil leak may happen in the oil lubricating system.

Replacing or repairing the crankcase ventilation valve will solve the issue.

Oil leaks around the piston and piston ring

Probable reasons | Diagnosis |

Spotted, damaged, or broken piston ring | Replacing the damaged oil ring and cleaning the oil ring deposits |

Rotting outside the cylinder wall | Installing oversized piston |

Cylinder block | Tightening the head nut with the right torque level |

3. Sound from the main bearing

Probable reasons | Diagnosis |

Insufficient oil supply | Check oil level. If necessary, change or replace the relief valve |

Low oil pressure | Oil level checking |

Diluted oil | Choose oil according to the appropriate oil viscosity |

Higher bearing clearance | Inspect the bearing clearance |

Excess end-play in the crankshaft | Inspecting the rotting level of the main bearing and flange |

Lose torque converter | Tightening to the right level |

4. Sound from the connecting rod

Probable reasons | Diagnosis |

Insufficient oil supply | Checking the oil level and relief valve |

Low oil pressure | Check oil level and other probable reasons |

Diluted oil | Drain out the oil and pour the right viscosity oil inside the chamber |

Higher bear clearance | Checking the bearing clearance level |

Out of round connecting rod journal | Grounding the journals |

Bended connecting rod | Replacing the connecting rod |

5. Sound from the valve

Probable reasons | Diagnosis |

Low or high oil level | Adding or subtracting oil to the chamber until the oil level comes to the right level |

Diluted oil | Adding the right viscosity oil |

Low oil pressure | Checking oil level |

Dirt in the valve tappets | Cleaning the valve tappets |

Bended push rod | Replacing the push rod |

Decayed rocker arms | Replacing the faulty rocker arms |

Decayed tappets | Installing new tappets |

Decayed valve guide | Rimming the valve guides and installing new oversized stem valves |

Higher runout in the valve phase and sit | Grounding the valve phase and sit |

Preventing malfunction in the engine’s oil lubricating system

Modern engines are equipped in a way that allows the users to take long intervals between oil changes.

It is recommended that one changes the engine’s lube oil after every 5,000 miles.

Extended oil change intervals can be a good reason why one may notice malfunctions in the lubricating system.

At the same time, proper maintenance is more than important to prevent any issues with the lubricating system.

Those who maintain both the car and all the organisms related to the vehicle are expected to get a better service both from the engine and the vehicle.